History

Presenting 65 years in the history of MEIKIKOU.

1950s

| 1955 | 3 | Nagoya kiko Co.,Ltd. was established in Atsuta-ku.Nagoya.(Capital: 1.5 million yen ) |

| 1957 | 6 | Increase in capital to 5 million yen Commencement of production of conveyors as in-house product |

| 1958 | 3 | Increase in capital to 9.5 million yen |

-

Nagoya Kiko headquarters in Atsuta-ku

Nagoya Kiko headquarters in Atsuta-ku

-

Roller conveyor at time of launch

Roller conveyor at time of launch

1960s

| 1961 | 7 | Completion of 1st stage of construction of Toyoake Plant |

| 12 | Increase in capital to 50 million yen | |

| 1962 | 10 | Establishment of sales offices in Osaka and Tokyo |

| 1964 | 3 | Completion of 2nd stage of construction of Toyoake Plant |

| 1966 | 10 | Increase in capital to 100 million yen |

| 1967 | 2 | Concentration of conveyor division at Toyoake Plant |

| 4 | Completion of 3rd stage of construction of Toyoake Plant | |

| 1969 | 12 | Conclusion of technical cooperation agreement for Scissor Lifts with American Manufacturing (USA) |

-

Toyoake Plant in 1961

Toyoake Plant in 1961

(Present head office and plant) -

Scissor Lifts M Series at time of agreement

Scissor Lifts M Series at time of agreement

1970s

| 1970 | 1 | Completion of 4th stage of construction of Toyoake Plant |

| 4 | Increase in capital to 200 million yen Establishment of in-house product system for conveyor and |

|

| 10 | Completion of Meiho Dormitory | |

| 11 | Conclusion of technical cooperation agreement for Positive Action Conveyors with John Burton Machine Corporation (USA) |

|

| 1971 | 5 | Conclusion of technical cooperation agreement for food machinery with Holstein & Kappert Inc.(Germany) |

| 9 | Conclusion of sales agreement for industrial robots with Robotics, Inc. (USA) and start of local manufacture |

|

| 12 | Conclusion of technical cooperation agreement for Accuma Flow with Litton Industrial Automation Systems Inc. (USA) | |

| 1974 | 5 | Conclusion of manufacture and sales agreement for breadmaking machinery with Hight Co., Ltd. |

| 11 | Relocation of company head office to Toyoake, Aichi prefecture | |

| 1977 | 11 | Development of Scissor Lifts N series |

| 1978 | 3 | Development of High Storage Flow (for medium and heavy loads) |

-

Hit product, Scissor Lifts N Series, equipped with MEIKIKOU’s original construction

Hit product, Scissor Lifts N Series, equipped with MEIKIKOU’s original construction

-

High Storage Flow, a compilation of MEIKIKOU’s technological capabilities, which received a Design Contribution Award from the Japan Society for the Advancement of Inventions. Patent obtained in the United States and Europe.

High Storage Flow, a compilation of MEIKIKOU’s technological capabilities, which received a Design Contribution Award from the Japan Society for the Advancement of Inventions. Patent obtained in the United States and Europe.

1980s

| 1980 | 5 | Establishment of Sendai and Shizuoka local sales offices |

| 1981 | 1 | Establishment of Kita-Kanto local sales office |

| 3 | Establishment of Kyushu sales office | |

| 5 | Development of Press Mate, a device for conveying loads between press processes | |

| 9 | Development of High Storage Flow (for light loads) | |

| 1983 | 7 | Development of Universal Flow |

| 1984 | 1 | Establishment of Scissor Lifts plant |

| 6 | Establishment of Hiroshima local sales office | |

| 10 | Conclusion of technical assistance agreement for Transcar (AGV) with Bureau Patent AG. (Switzerland) | |

| 1985 | 5 | Change of company name to Meikikou Corporation |

| 8 | Establishment of Kanagawa local sales office | |

| 1987 | 8 | Conclusion of technical cooperation agreement for Zero Pressure Accuma Flow with Logan Conveyors (USA) |

| 1989 | 10 | Establishment of Keiji (Kyoto-Shiga) and Kanazawa local sales offices |

-

Press Mate, which received a Design Contribution Award from the Japan Society for the Advancement of Inventions. Patent obtained in the United States. This product contributed to the automobile industry.

Press Mate, which received a Design Contribution Award from the Japan Society for the Advancement of Inventions. Patent obtained in the United States. This product contributed to the automobile industry.

-

Transcar, used in new markets of hospitals and hotels.

Transcar, used in new markets of hospitals and hotels.

1990s

| 1990 | 3 | Establishment of Development Center |

| 1992 | 3 | Establishment of Technical Center |

| 10 | Development and launch of TRUCK-U-LAYTOR, a system for loading and unloading trucks | |

| 1993 | 5 | Establishment of Kumagaya local sales office |

| 8 | Establishment of Shikoku local sales office | |

| 1995 | 3 | Development and launch of Scissor Lifts Hyper Series |

| 12 | Development and launch of Scissor Lift Endeavor Series | |

| 1996 | 4 | Development and launch of Epoch Flow Series |

| Establishment of Meikikou Techno Corporation | ||

| 1997 | 4 | Development and launch of Cam Diverter, a lifting device used to change carrying direction 90°at conveyor intersections |

| 10 | Establishment of Clean Shop, a dedicated assembly shop for LC panels and semiconductor handling machines | |

| 1998 | 10 | Exhibit at Logis-Tech Tokyo 1998, Asia’s largest material handling and logistics exhibition |

| Development and launch of New Vander-Devander | ||

| 11 | Development and launch of Scissor Lifts Jasper Series | |

| 1999 | 1 | Development and launch of Scissor Lifts Long Table Series and Tough Series |

| 7 | Development and launch of Scissor Lifts Caribou Series and New Endeavor Series | |

| 10 | Development and launch of Scissor Lifts Power Arm Series | |

| ISO9001 certification |

-

TRUCK-U-LAYTOR when launched.

TRUCK-U-LAYTOR when launched.

-

1616 models, Hyper Series

1616 models, Hyper Series

-

Ball screw drive Scissor Lifts Endeavor series.

Ball screw drive Scissor Lifts Endeavor series.

-

Epoch flow series.

Epoch flow series.

-

Clean Shop.

Clean Shop.

-

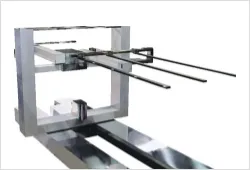

Lifting device to change carrying direction at conveyor intersections Cam Diverter

Lifting device to change carrying direction at conveyor intersections Cam Diverter

-

Exhibit to Logis-Tech Tokyo 1998.

Exhibit to Logis-Tech Tokyo 1998.

-

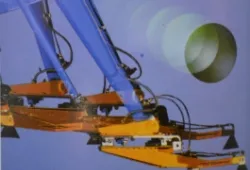

Devander for marine container.

Devander for marine container.

-

Devander for General.

Devander for General.

-

Small-sized Ball screw drive Scissor Lifts Jasper series.

Small-sized Ball screw drive Scissor Lifts Jasper series.

-

Scissor Lifts Long table series.

Scissor Lifts Long table series.

Scissor Lifts Tough series. -

Scissor Lifts Caribou series.

Scissor Lifts Caribou series.

Scissor Lifts Endeavor series. -

Scissor Lifts Power arm series.

Scissor Lifts Power arm series.

-

ISO9001 JQA-QM4011

ISO9001 JQA-QM4011

2000s

| 2000 | 4 | Development and launch of extra-low-profile Scissor Lifts Stingray Series |

| 10 | Development and launch of Pallet Flow Series | |

| Exhibit at Logis-Tech Tokyo 2000, Asia’s largest material handling and logistics exhibition | ||

| 2001 | 6 | ISO14001 certification |

| 8 | Launch of 45 Scissor Lifts models, including Endeavor Series 2-Stage Type | |

| 2002 | 7 | Development and launch of Rapid Flow Series of high-speed conveyors |

| 8 | Development and launch of clean robot for 5th-generation LC panel substrates | |

| 11 | Development and launch of Scissor Lifts Clean Series for cleanrooms | |

| 2003 | 4 | Merger with Meikikou Techno Corporation. |

| Development and launch of wheelchair lift, Level | ||

| 12 | Development and launch of clean robot for 6th- and 7th-generation LC panels | |

| 2004 | 2 | Launch of three types (120mm/180mm/240mm stroke) of Cam Diverter |

| 2005 | 3 | 50th anniversary of company’s foundation |

| 6 | Launch of 22 models of narrow-width Endeavor Series Scissor Lifts with ball screw drive | |

| 2008 | Receipt of Chubu Science and Technology Center Promotion Award for development of air floating conveyor for LC panels | |

| 2009 | 5 | Development and launch of Chain Live Roller Flow Series and Whisper Flow Series |

-

Extra low floor Scissor Lifts “Stingray series”.

Extra low floor Scissor Lifts “Stingray series”.

-

Pallet conveyor, Pallet Flow Series

Pallet conveyor, Pallet Flow Series

-

Exhibit to Logis-Tech Tokyo 2000

Exhibit to Logis-Tech Tokyo 2000

-

ISO14001 JQA-EM1653

ISO14001 JQA-EM1653

-

Scissor Lifts “Endeavor series”.

Scissor Lifts “Endeavor series”.

-

High speed Conveyor “Rapid flow series”.

High speed Conveyor “Rapid flow series”.

-

Clean Robot for the fifth generation LC panel

Clean Robot for the fifth generation LC panel

-

Scissor Lifts for cleanroom “Clean series”.

Scissor Lifts for cleanroom “Clean series”.

-

Wheelchair lift “level”.

Wheelchair lift “level”.

-

Clean Robot for the sixth and seventh generation LC panel

Clean Robot for the sixth and seventh generation LC panel

-

Lifting device to change carrying direction at conveyor intersection Cam Diverter

Lifting device to change carrying direction at conveyor intersection Cam Diverter

-

Narrow type Endeavor series.

Narrow type Endeavor series.

-

Chain drive Conveyor “Chain live roller flow series”.

Chain drive Conveyor “Chain live roller flow series”.

-

Flat belt drive Conveyor “Whisper flow series”.

Flat belt drive Conveyor “Whisper flow series”.

2010s

| 2010 | 1 | Launch of four 200-kg models in Endeavor Series Scissor Lifts with ball screw drive |

| 2011 | 12 | Development and launch of Wash Series |

| Launch of nine 3-tonne and 4-tonne models in Endeavor Series Scissor Lifts with ball screw drive | ||

| 2013 | 6 | Debut exhibit at FOOMA JAPAN |

| 7 | Establishment of local sales office in Okayama and contact office in Hiroshima | |

| 9 | Debut exhibit of wheelchair lift, Dansa-Racooda, at HCR | |

| 2014 | 5 | Debut exhibit at Welfare exhibition |

| 6 | Minister of Land, Infrastructure and Transport authorization for ball screw drive wheelchair lift, Dansa-Racooda AS1000/AS1500 | |

| 2015 | 1 | Ministry of Land, Infrastructure and Transport certification for Dansa-Racooda AF600 |

| 3 | 60th anniversary of company’s foundation | |

| 4 | Debut exhibit at Barrier Free exhibition | |

| 2017 | 5 | Establishment of Kita-Kanto sales office |

| 12 | Development of high accuracy Scissor Lifts, G-servo Endeavor | |

| 2018 | 5 | Provision of podium lifts for inaugural Para Powerlifting Championships in Kyoto. Attracts media attention as the first liftable podium for wheelchair sports in Japan. |

| 6 | Development of bellow-type expandable conveyor, Groovy-X Flow. Exhibited for first time at FOOMA JAPAN 2018 |

|

| 2019 | 7 | Development of pallet loading-unloading system for trucks. Exhibited for first time at FOOMA JAPAN 2019. Featured in newspapers and attracts many inquiries. |

| 12 | Debut exhibit at International Robot Exhibition Development of DC-powered DC Endeavor and DC Cam Diverter.。 Exhibited for first time at International Robot Exhibition 2019. Development of DC-powered Block Module Conveyor. Exhibited for first time at International Robot Exhibition 2019. |

-

Ball screw drive Scissor Lifts Endeavor series for 200kg.

Ball screw drive Scissor Lifts Endeavor series for 200kg.

-

Wash series

Wash series

-

Ball screw drive Scissor Lifts Endeavor series for 3ton and 4ton.

Ball screw drive Scissor Lifts Endeavor series for 3ton and 4ton.

-

Exhibited for first time at FOOMA JAPAN

Exhibited for first time at FOOMA JAPAN

-

Debut exhibit of wheelchair lift, Dansa-Racooda, at HCR

Debut exhibit of wheelchair lift, Dansa-Racooda, at HCR

-

Debut exhibit at Welfare exhibition

Debut exhibit at Welfare exhibition

-

60th anniversary of company’s foundation

60th anniversary of company’s foundation

-

Debut exhibit at Barrier Free exhibition

Debut exhibit at Barrier Free exhibition

-

Development of high accuracy Scissor Lifts “G-servo Endeavor”.

Development of high accuracy Scissor Lifts “G-servo Endeavor”.

-

Japan’s first liftable podium for wheelchair sports

Japan’s first liftable podium for wheelchair sports

-

Bellow-type expandable conveyor, Groovy-X Flow

Bellow-type expandable conveyor, Groovy-X Flow

-

Exhibit to “FOOMA JAPAN 2019”.

Exhibit to “FOOMA JAPAN 2019”.

-

Debut exhibit at International Robot Exhibition

Debut exhibit at International Robot Exhibition

-

DC Endeavor and DC Cam diverter.

DC Endeavor and DC Cam diverter.

-

Block module conveyor.

Block module conveyor.

2020s

| 2020 | 1 | Certification as 2019 Aichi-Brand Company as an outstanding manufacturer (Certificate No. 1506) |

| 3 | 65th anniversary of company’s foundation |

-

Aichi-Brand Company Certificate No. 1506

Aichi-Brand Company Certificate No. 1506